Cryogenic Turboexpanders

Cryogenmash offers a wide range of cryogenic turboexpanders, meeting entirely both the company internal needs and any customer’s demands.

Our standard items updating performed within last 10 (ten) years – reduction turboexpanders with brake electric power generators, as well as innovation developments, aimed to creation of new types of design where the compression stage is used as brake, contributed to wide recognition of turbomachines made by Cryogenmash.

Turboexpander – LP and MP compressor sets, production of which started since 1993 and are successfully operated in Russia and China till now. Their high thermodynamic effectiveness (performance factor to 89 %), combined with the expander capacity for additional compression of working gas in the compressor stage, improves essentially the engineering-and-economical performance of the modern ASPs.

Similar in design turbosets equipped with a brake compressor became common use in various thermostatting systems, particularly as a part of space sea launch complex "Sea Launch".

Since 1996, Cryogenmash started production of the ASU turboexpanders on gas bearings, previously used in turbomachines of helium liquefiers only. Positive operating experience within more than 6 (six) years at Uzbek integrated iron-and-steel works (Bokhara town) gives evidence of their high quality and safety.

Developed and implemented was a special modification procedure for the turboexpanders produced and operated before directly at Customers’. Substitution of the air-gas channel elements for improved ones, while the bearings – for more safe ones, makes it possible not only to extend the turboexpanders service life, but to improve substantially the ASU performance.

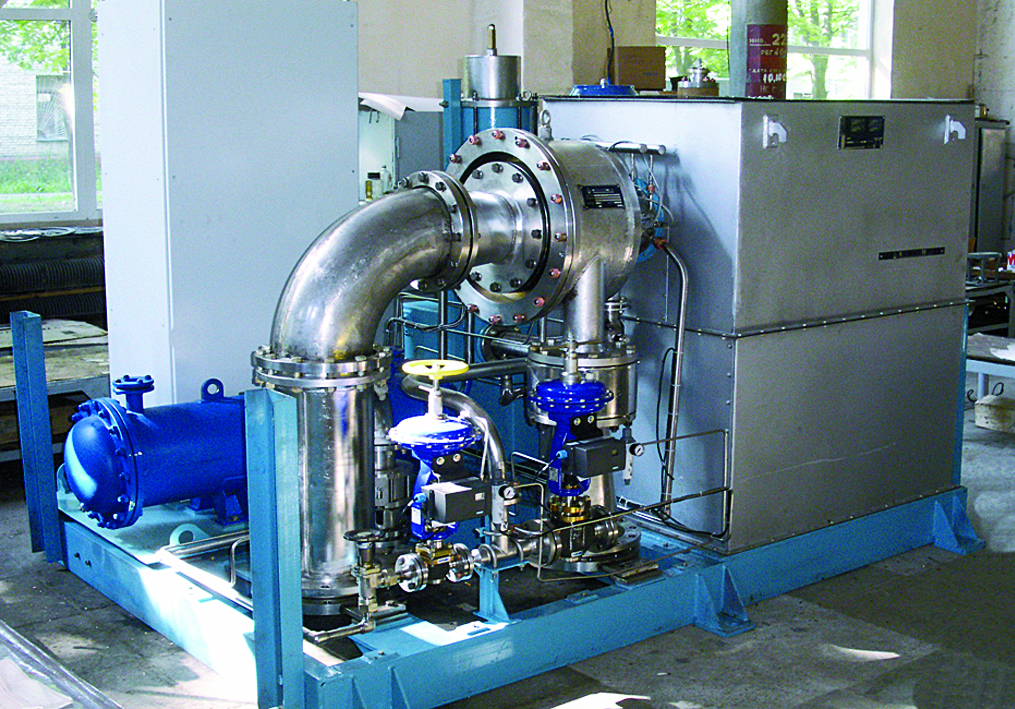

The turboexpanders development modern concept assumed at Cryogenmash, lies in development of packaged units equipped with the up-to-date instruments for their monitoring, at the minimum scope of mounting and commissioning works.

You may trust implicitly to our 50-years experience in development of the high-quality turboexpanders – the first prototypes are under operation until now.