PJSC “Cryogenmash” provided its solutions at exhibition “Import substitution in gas industry” within the Х St. Petersburg International Gas Forum - 2021

11.10.2021

From 5th to 8th of October PJSC “Cryogenmash” (member of OMZ Group) provided its solutions at exhibition “Import substitution in gas industry” within the Х St. Petersburg International Gas Forum - 2021.

The tank is 2-wall cylinder apparatus, consisting of the vessel and the jacket. The vessel with liquid hydrogen inside is manufactured from stainless steel. To exclude the heat leaks to the product, multilayer screen-vacuum insulation is applied over the vessel; evaporation losses are less than 0,3% a day. The mass of liquid hydrogen stored – 15 700 kg, working temperature – minus 259ºС, working pressure is equal to 1 MPa. The tank length - 36,3 m; the dimensions allow transporting the finished and factory-tested item to the Customer site by road and rail. The company manufactured many cryogenic complexes for the ground based development of rocket engines and stages, rockets fuelling at launchers, and means of liquid hydrogen transportation for considerable distances.

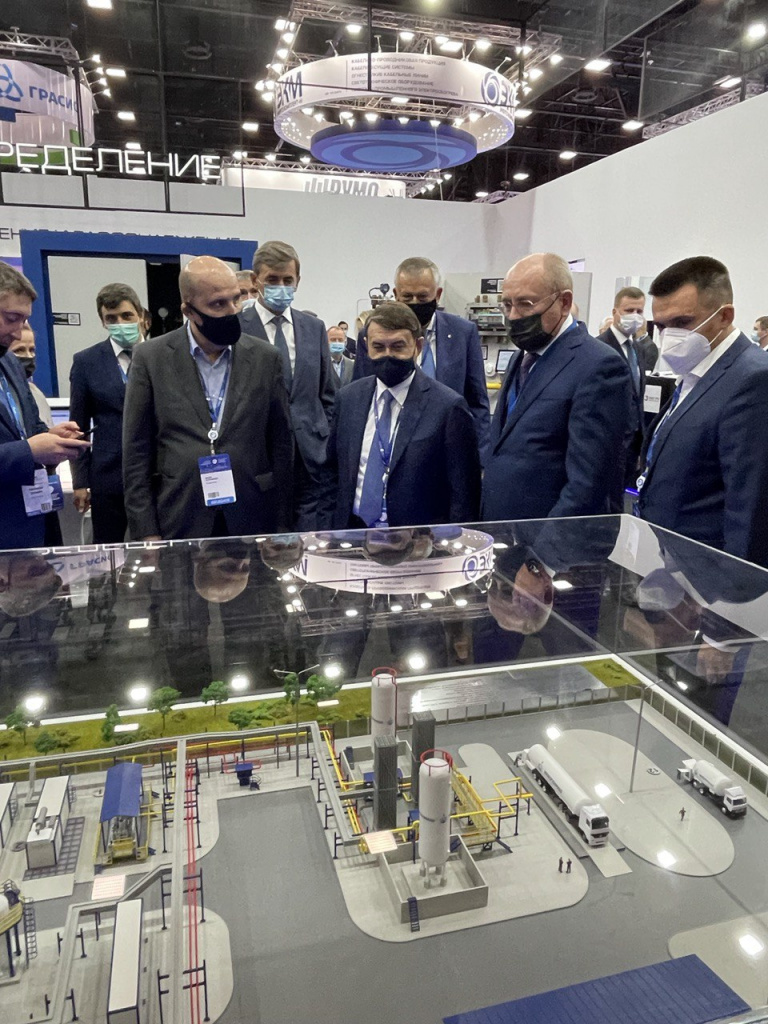

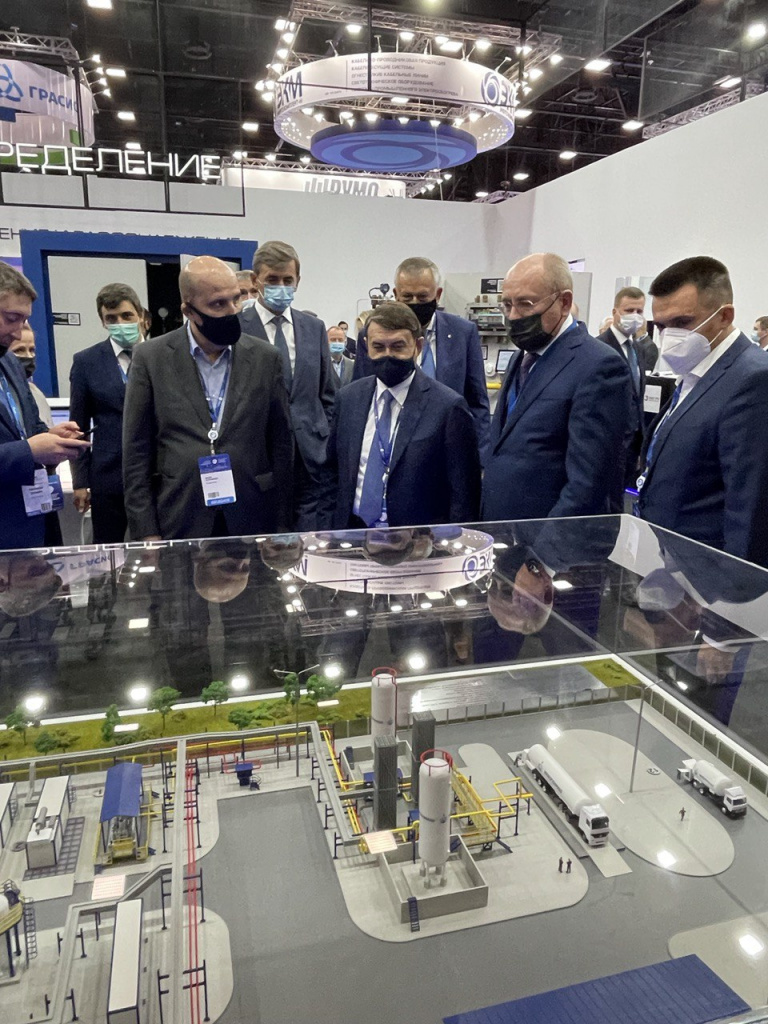

The forum visitors, specialists, PJSC “Gazprom” management familiarized with the model of standard low-tonnage natural gas liquefaction plant, with capacity of 1,5 tons of LNG per hour, including the LNG storage, transportation and filling systems.

“Cryogenmash” has manufactured already a set of natural gas liquefaction plants, working on subcooling high pressure throttling-ejection cycle. Principle diagram of these plants joins the simple structure and operation with high energy efficiency. More than 20 plants of this type are operated successfully both in Russia and abroad, within the production range of LNG from 0.5 t/hr to 3 t/hr.

Besides, the visitors of test bench were interested in the model of unique fixed cryogenic storage system of liquid hydrogen (250 m3) developed by “Cryogenmash”.